The manufacturing industry has been undergoing a dynamic shift towards digitalisation. Advancing technology, sensors, connectivity and the ability to store vast amounts of data has encouraged manufacturing owner-operators to converge IT and OT and utilise machine data to gain useful insights. But, despite the clear benefits of digitalisation, companies are encountering challenges with the adoption of advanced analytics tools and getting value out of all the available technologies. These challenges have different perspectives for each industry but are especially highlighted when it comes to the engineering and metal cutting industries.

Sandvik Coromat, a world’s leading supplier of manufacturing and metal cutting tools, went through a similar data-driven journey in the adoption of analytics in their business.

V R Vijay Anand, Head of Digital Machining at Sandvik Coromant, brought their experience closer to us at the Maintenance Analytics Summit with implementing data analytics in processes, challenges they had and learnings they took away from it.

Transformation of engineering driven by technology

No doubt, rapid technological advancements are transforming the very definition of engineering, explains Vijay. The challenge that the industry faces is how to adopt all the different technologies and what is the real value it brings to companies.

Some of the challenges the metal cutting industry is experienced where advanced analytics may give some relevant insights are:

- Reducing waste – all industries from automotive, airlines, oil and gas are seeing ways to be more productive, reduce time, resources, consumables, and be more predictive in the production.

- Skill gap – Technical skills and competences with metal cutting are difficult to source. Unfortunately, new generations are reluctant to go into traditional professions like engineering. Analytics can help companies become independent of individuals with knowledge and move towards a more predictive and prescriptive way of working.

- Automation – To be competitive on the market, our customers must increase their level of automation. The key question is how to leverage the investment into and value of automation.

- Cost and quality control – Managing production in terms of customisation, smaller batches and shorter lead times, which requires cost traceability and producing the ”right” quality for the customers to be competitive.

When metal-cutting companies are implementing digital technologies and leveraging data insights to help their customers, it all comes down to solving the above challenges, states V R Vijay. And solving them requires the ability to leverage information and knowledge through data and analytics.

“The true challenge that we face as an industry is the concept of data and treating analytics as technology vs the true value that comes out of this data. When we start talking about analytics, data, IoT and all sources of data, we lose the aspect of how we can use all this data to create true value”, argues Vijay in his Data Talks interview. He suggests that rather than taking a bottom-up approach focusing on data sources, we would be more successful starting from the top thinking about the value we want to create.

Two worlds in the engineering industry: analytics producers and consumers

However, in engineering, the term “analytics” means different things for people producing analytics and people consuming it, claims Vijay.

The analytics producers are all the data scientists and data analysts who are playing with the data, trying to find trends in it and come up with value from data. The analytics consumers are traditional operators in a manufacturing plant standing in front of the machines. The consumers don’t really care about data or analytics; their job is to make sure the machine is working properly.

These are two opposite worlds in the metal cutting industry that have two different understanding of what analytics means. When a data scientist refers to predictive analytics, and when a traditional engineer refers to predictive analytics, their understanding is diametrically different.

For analytics experts, predictive means that they are past descriptive and diagnostic analytics, and can produce predictions and insights about the future. While for the machine operator, a change in the machine dashboard descriptive numbers, combined with the sound of vibration (his sound) and a small stray in the cutting path (his vision) are indicating that something is wrong or might be going wrong really soon.

There’s a gap between what analytics producers want to produce and what consumers expect as a value from it. This gap is the reason for the moving target of the ROI from analytics, emphasises Vijay.

In order for both worlds to start using the same language of data and start seeing predictive analytics through the same eyes, Vijay suggests discussing why it’s better to leverage data and how it can help perform maintenance in a simpler, more accurate automated way than the corrective maintenance traditional operators are doing.

The true value of data analytics in metal cutting comes when the goal of analytics is put in the context of technical operators who are expecting some value out of it.

Sandvik Coromant’s analytics to insights journey

Sandvik Coromant went through a maturity journey from analytics to insights before seeing any tangible value. Vijay described that at the beginning, they saw analytics as a technology enabler. Their focus was on building platforms and technologies, assuming they know what brings value from predictive analytics for the operators.

After several years, they can present their three significant learnings from the journey:

- Putting business value before everything else – analytics is not about introducing new technology or sources of data; it’s about how to monetise on all the data we have.

- Having a technology strategy that can support changing dynamics – creating a technology enabler and an ecosystem which helps to scale, rather than creating siloed analytics applications

- Insights are not an independent organisation standing by itself; they should be an integral part of the core business.

Let’s explore further how Sandvik Coromant addressed each aspect separately.

Business value before everything else

Vijay that they succeeded in putting business value first by moving away from technology and stated the maturity journey of getting insights from

- Descriptive (Digital technology for visualising production processes) to

- Adaptive (Insights-driven preventive and predictable process management) to

- Autonomous (Self-learning technology enabling autonomous factories).

But the key is to be able to do the descriptive or diagnostic tier successfully to achieve business value in terms of monetisation, savings, improving efficiency and predictability, declares Vijay. The next tiers – adaptive and autonomous analytics will follow suit if the foundation is done right. The success of analytics and insights starts on the descriptive level.

Technology strategy that can support changing dynamics

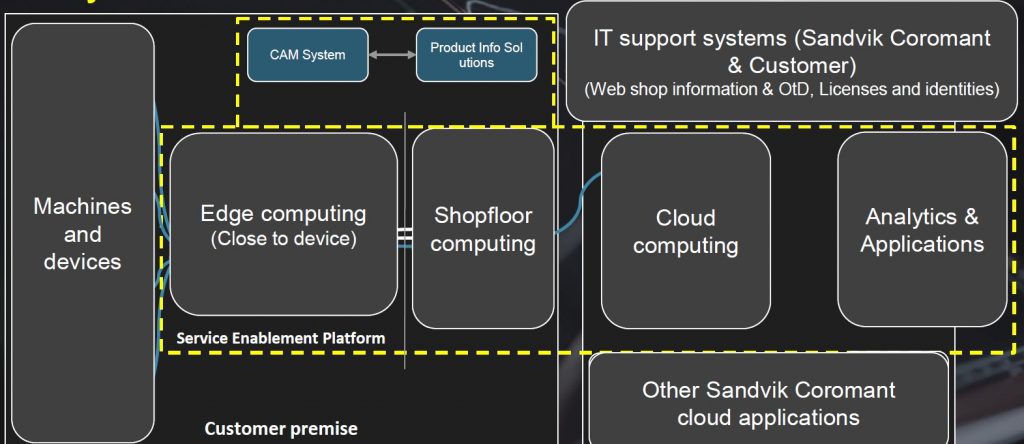

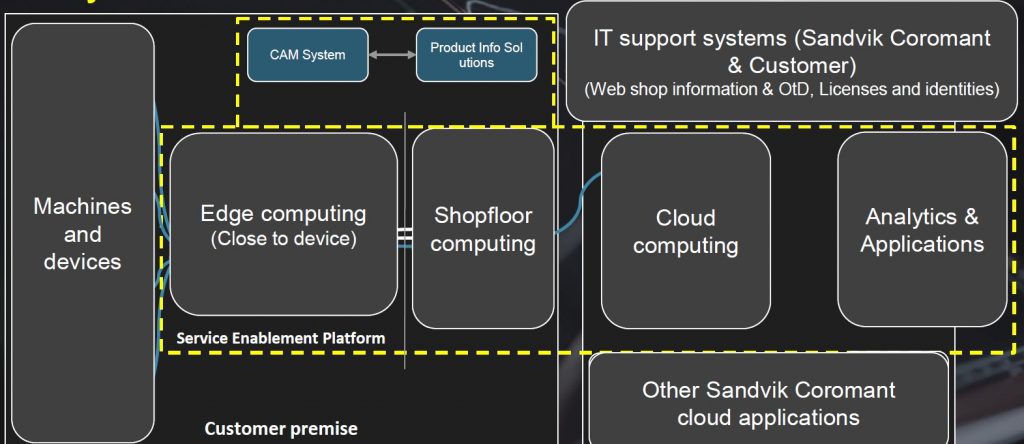

Analytics and intelligence should be integrated into each layer of the data pipeline, from the machines and devices, to edge computing, shop-floor computing, cloud computing to analytics applications. Analytics can’t be isolated in only analytics applications or computing. And the technology strategy should support the analytics in all layers from the machines to the cloud.

Insights organisation should be an integral part of the core business

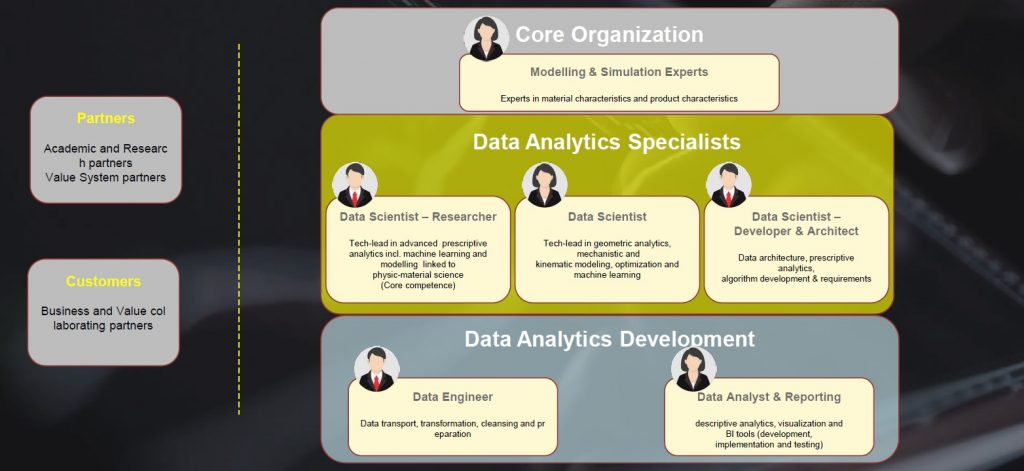

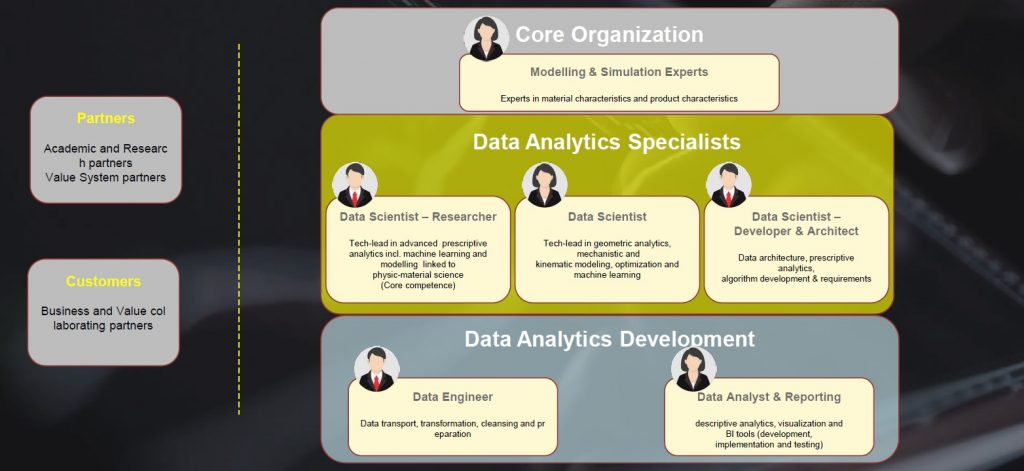

Insights should be independent of the core organisation, states Vijay. The core is where it all starts, and insights should be complementing it. In the metal cutting industry, the fundamentals are in physics and chemistry, materials used for cutting, product-related characteristics and the domain knowledge of where these products are applied. Only after all these components, come the capabilities and skills of writing algorithms, trends of data and creating a programme that makes predictions.

As we can see from the graphic, the Sandvik Coromant structure starts with the core foundations of technical domain knowledge and experience that feeds the analytics and software. This way, they can create value based on the overall knowledge and expertise within the organisation, complemented by their partners and customers.

However, advanced analytics is a journey, Vijay repeats, and it has gone through many cycles. From what we can see, the metal cutting industry is in the cycle where they have started seeing analytics from the business value perspective, and not just as a technology.

Add comment