Digital twins bridge the gap in complex assets between OT systems and the IT environment by capturing data to monitor performance, deterioration and failure, location and safety compliance and remote monitoring systems for scheduling and asset utilisation.

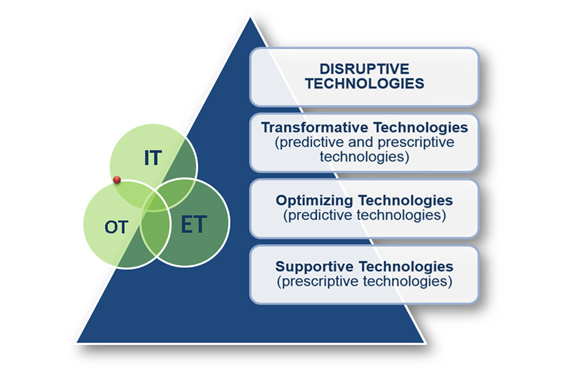

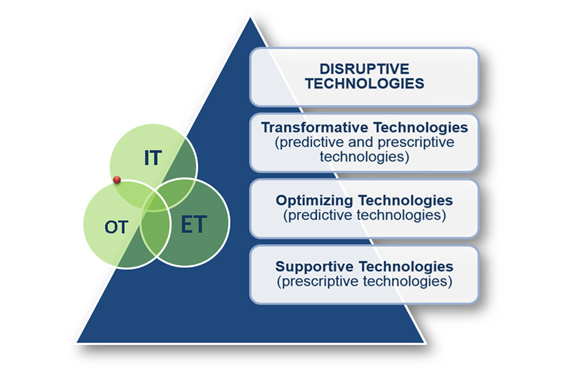

Digital transformation demands that engineering technology (ET) be included in the IT/OT convergence process powered by IITo as the importance of integrating product design increases.

Diego Galar, Professor at the Luleå University of Technology and a regular Data Innovation Summit speaker, is coming to the 5th edition to discuss the maturity of digital twins as IT/OT/ET convergence outcome and what we can expect from them. We caught up with him beforehand to talk to him about the current state of the digital twins and digitalisation in the manufacturing industry.

Hyperight: Hello, Diego, we are happy to welcome you once again at the Data Innovation Summit stage. As you have already been featured in an article and had your Data and AI Innovators interview on our Hyperight Read channel, our readers know you are the industry expert when it comes to IoT and Industrial AI.

The topic of digital twins is a recurring one recently as a method for managing, monitoring and maintaining assets differently. One year ago, you talked about the need for cognitive analytics and digital twins 4.0. What’s the current state of the industry regarding this?

Diego Galar: Certainly, Digital Twins are a hot topic. Honestly speaking, everybody has their idea about what a digital twin is, so it’s really challenging to assess the real status in the industry. However, most of us agree on some common basis to define a twin as virtual and digital representations of physical entities or systems. It involves connected “things” generating real-time data which is analysed and combined with other data related to the context around it.

The twins can be then presented to OEMs, operators or maintainers in a variety of roles, so they can remotely understand asset condition, performance, configuration. In summary, twins are entities which reproduce the functionality of our assets and where performance can be monitored and failure forecasted. What industry demands is crystal clear, the achievements so far are modest.

Actually, I like to say that digital twins are like the book “The Picture of Dorian Grey” by Oscar Wilde where the author can see the ageing in the portrait while he is preserved young and fit. Industry demands precisely that, the portrait to see the future ageing of assets while they are up and running. In this regard, the industry has found the way and it’s moving towards this idea but slowly since we are paving the way while walking.

Hyperight: Yet, it’s undeniable that digital twins carry particular challenges with them. What are some of them?

Diego Galar: The creation of a digital twin is challenging since we need to engineering and data science to converge. It is a co-creation between traditional engineers and AI. That convergence is not easy due to lack of standards, experience and difficulties bridging the gap between analytics and domain knowledge.

Moreover, digital twins of complex systems need to integrate twins of different subsystems and components that eventually should be provided by global suppliers, and we are not used to supplying product and twin to be integrated into a complex asset. For example, if we try to twin a windmill, we expect bearing manufacturers, or blade manufacturers to supply the twins of those parts seamlessly to be integrated. This is because as end-users, we cannot face the twinning process of huge and complex assets which require extensive engineering work.

In this regard, the twins provided can be transparent boxes or black boxes, i.e. the supplier may open the models for us or give the black box to be part of our bigger twin without in-depth knowledge about the twin of specific components. This makes sense since digital twins shared by multiple stakeholders must provide benefits preserving the intellectual property of all involved parties.

Hyperight: What are the most significant benefits of integrating digital transformation and IoT in the manufacturing industry?

Diego Galar: Digitization in manufacturing is moving industry to the concept of dark factories, i.e. factories without human intervention in operation or maintenance. This concept is haunting industrialised countries. It is dark because there aren’t any people in it and there is no need to turn on the lights. Machines will do all the work. If this vision were to become a reality, it would challenge the very foundations of our societies. Some people get scared about this concept thinking it will destroy jobs. But it is the other way around, some of the jobs don’t make sense anymore, while other more qualified and better paid are created moving towards a more advanced and comfortable society.

We cannot neglect that factories will dramatically change. We will be able to see the product before it is manufactured thanks to the virtual commissioning and predict any shutdown or performance slowdown beforehand thanks to the digital twins of our production lines. This will end up in real lean, robust and resilient manufacturing.

Hyperight: According to a 2018 McKinsey survey, despite enthusiasm for digital manufacturing, few companies have realised its potential at scale. They are experiencing “pilot purgatory” in which they have significant activity underway but are not yet seeing meaningful bottom-line benefits from this. Has this changed almost two years later?

Diego Galar: It is, unfortunately, true that our expectations for 2020 have not been materialised and thinking of “Back to the Future” movie with the Delorean travelling to 2015 was too optimistic. We indeed know the potential of digitisation, myths and pitfalls, common mistakes, and now we are prepared to face the transformation and convert all pilots in success stories deployed all over our industries. In the current situation, 2020 as the deadline has been “adjusted”, and we expect to be there by 2030. Indeed, we underestimated the barriers of the digital transformation and did not find on time the proper balance between enabling technologies for digital transformation and traditional engineering knowledge (ET).

Honestly speaking the main reason for this failure in the process of scaling up the pilots and demonstrators is the one-sided efforts in digitisation, i.e. end-users trying to twin the assets and move to digital factories without the support of global suppliers. Indeed, many manufacturers tried to create digital replicas of their assets towards 4.0 prototypes without the OEM of those assets. This is obviously a nonsense task since reverse engineering, and tremendous efforts are required but mean that end-users did not understand the real meaning of digital manufacturing. The digital factory is the place where OEM and end-users get together to provide design experience and data from the field, respectively.

Another problem is within the companies. Historically, the information technology (IT) and operational technology (OT/operations) departments within a manufacturing company have functioned somewhat independently. Operations kept the assets running and, while IT-managed business applications from the front office. The IT/OT relationship must also change to keep up.

Top performers in digital transformation recognise that the operational data they use to support real-time decision-making could create additional value for the company. But this data must be merged with IT data in a meaningful way. With this fusion, IT will help OT align with business systems. But to get there, IT needs the knowledge and support of OT, as operations departments understand and control the assets.

Hyperight: In your Data and AI Innovators interview, you presented your outlooks for data and analytics. But what are your predictions when it comes to digital factories? Are we going to see fully digitalised manufacturing any soon?

Diego Galar: We will see the digital factory soon since it is the only way to survive in the global economy. Business models are imposing a dramatic shift with customers more demanding and experienced who want new products more often.

Digitisation and twins are redefining the relation between OEMs and end-users, forcing them to work together and using the enabling technologies to meet their business goals. In a few words, digitalisation is not an option; it is the road ahead to survive or be left out.

But business and profit for companies is not the only driver for digitisation; digital transformation is the engine to power sustainability and circular economics framing what we call “sustainable manufacturing”. With the power of digital manufacturing, the waste will be minimised, energy consumption will be more efficient, and the supply chain will turn to circular instead of linear removing the traditional waste routes and making our manufacturing more environmentally friendly. We can conclude that digital manufacturing not only changes the way of doing business but also improves the societal responsibility of factories.

Add comment