Many industrial and manufacturing companies have their data stored in file systems and ERPs. But, if data scientists and engineers are to use this data to provide value from it, it has to be available and accessible in a consolidated cloud space.

Konstantinos Michail, IoT – Cloud Tech Lead at Nilfisk, will be presenting how companies can go through this shift to the cloud more quickly and efficiently, in his session at the Maintenance Analytics Summit.

Hyperight: Hi Konstantinos, we are really happy to have you with us at the virtual edition of the Maintenance Analytics Summit. To start, please tell us a bit about yourself, your background and your role at Nilfisk.

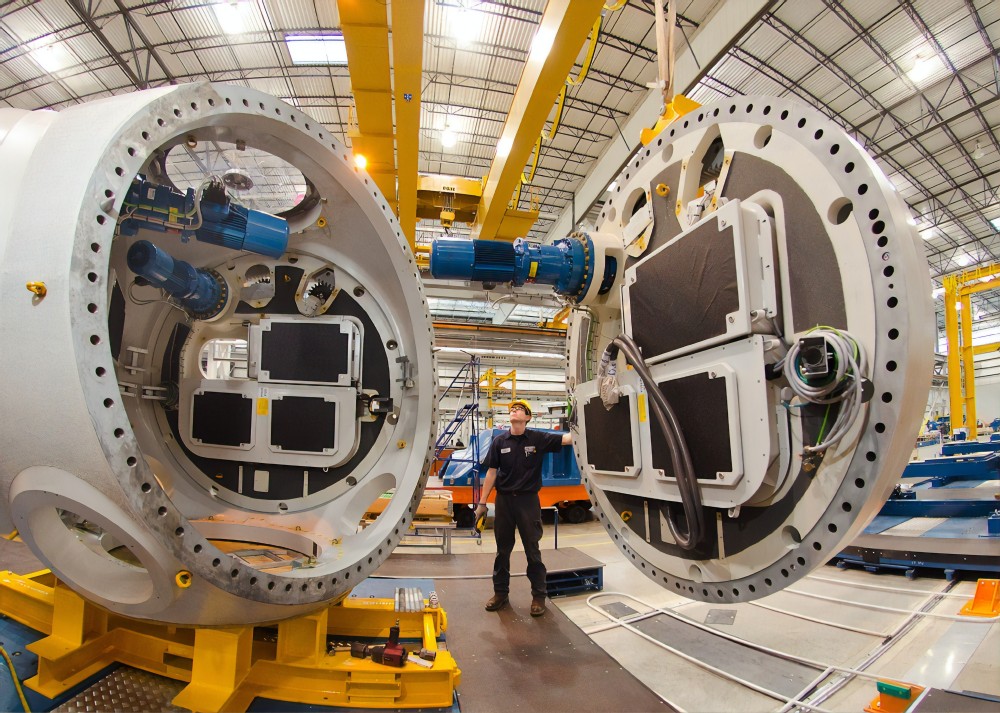

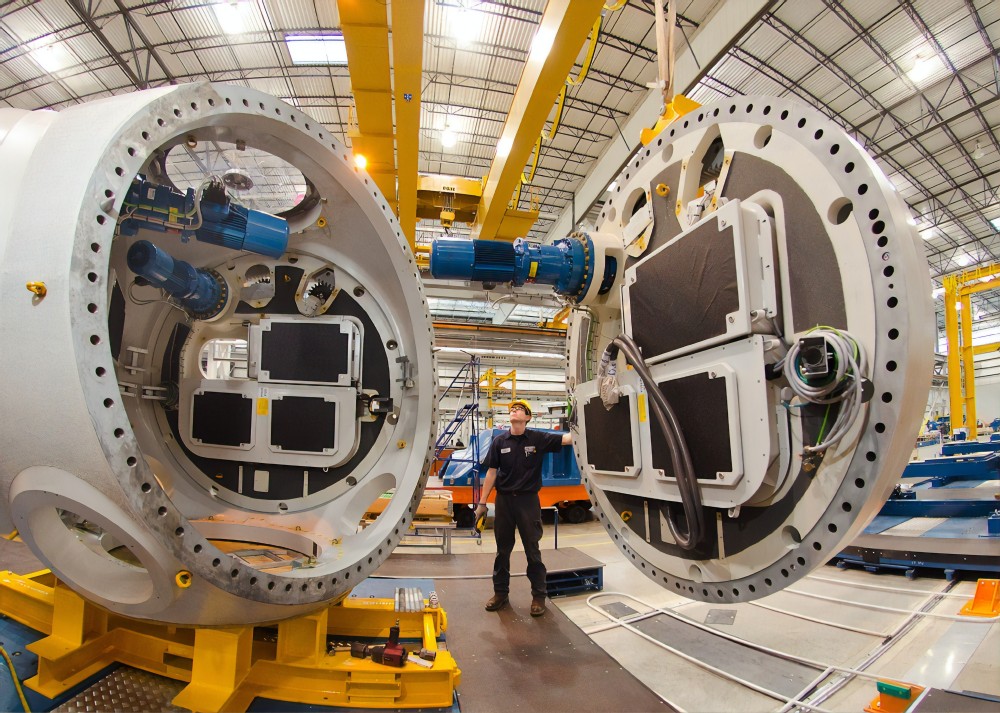

Konstantinos Michail: I am a passionate technologist and engineer that loves using cutting edge technologies to solve hard problems. As the Technology Lead of the Nilfisk IoT platform, I evaluate and adopt cutting edge technologies to extend our digital offerings and capture the ever-changing customer needs. Initially, the goal of our platform is to support our service organization to be able to have a better understanding of the history of a machine when they go out and serve our customers. It also supports our R&D organization to improve our machines and prioritize their efforts.

Hyperight: You are going to present Predictive Maintenance through the Cloud-based Approach. Could you please reveal to us more about how the cloud-based predictive maintenance? What are the benefits of it?

Konstantinos Michail: Many industrial and manufacturing companies have huge data collections stored in file systems (e.g. Historians) and their ERPs applications. Following a cloud-based approach, an organization has to make the data available and accessible in a consolidated cloud space (e.g. a Data Lake) so that the data scientists and engineers can leverage all the standard platform components to work with the data efficiently and generate value faster and more consistently. The paradigm, in general, is to have the data closer to the compute and use of standard cloud platform services to create experiments that are easier and faster to reproduce. Last but not least, most of the cloud vendors offer the ability to be able to push intelligence to the edge. This way, maintenance teams can implement automation processes to safeguard critical equipment by minimizing the time to action when an alert is raised due to an anomaly.

Hyperight: What would you say are the hinders for companies in implementing predictive maintenance? And what actions can be taken to surpass these hinders?

Konstantinos Michail: Predictive maintenance is a journey, and like any other journey, there are many challenges to overcome. The distributed landscape of data, responsibility and ownership is among the biggest challenges that large enterprises face when designing predictive maintenance applications. Data related to maintenance exist in ERPs, in emails, in file systems and, believe it or not, still on paper. Additionally, in many cases, different vendors (OEM) manage and own the data of their customer equipment who usually have other agendas and priorities and lack business models that monetize the data that their equipment produces.

Hyperight: According to you, what are the trends with maintenance analytics we can expect in 2020?

Konstantinos Michail: My expectation is that more and more advanced maintenance analytics applications will be implemented successfully and become something more than proof of concepts. Most organizations are still learning how to unlock the full potential of their data and are actively trying to bring the data landscape in a modern state. The adoption of machine learning and the hiring of relevant talent has proven to be more difficult than anticipated. As any other concept, the most significant challenge is to bridge the gap between people, technologies and processes and whoever gets there first, will gain a significant competitive edge.

Hyperight: And finally, experts are talking about the next level of maintenance based on cognitive analytics where AI systems are able to autonomously learn from past actions, find correlations, learn from outcomes and give prescriptions. Do you see it happening any soon in the industry, what are your future outlooks for cognitive maintenance?

Konstantinos Michail: Cognitive or prescriptive maintenance is a new mindset for many large organizations. It helps companies change their focus from reactive to prescriptive. It is the last part of a long journey, and only those who have mastered the predictive maintenance space can reach. But it is definitely worth getting to the ultimate understanding of how to approach maintenance holistically so that organizations thrive and stay competitive in a connected world.

Add comment